Biodegradable Waste to Energy Power Plant

Biodegradable Waste to Energy Power Plant Specification

- Gross Calorific Value

- 3500-4500 kcal/kg

- Dimension (L*W*H)

- 12m x 5m x 6m (sample for reference)

- Coal Calorific

- Not applicable; uses biodegradable waste

- Size

- Custom/Variable depending on requirement

- Product Type

- Waste to Energy Power Plant

- Material

- Mild Steel, Stainless Steel, Other Alloys

- Shape

- Rectangular/Modular

- Moisture (%)

- 10-25%

- Sulphur Content (%)

- < 0.6%

- Fixed Carbon

- 20-30%

- Phosphorus Content (%)

- < 0.2%

- Volatile Matter (%)

- 30-45%

- Ash Content (%)

- 18-28%

- Weight

- 8-25 Tons (varies by capacity)

- Cooling System

- Water or Air cooled

- Power Source

- Electricity/Biodegradable Waste

- Color

- Grey/Green/Custom on request

- Installation Type

- Turnkey/EPC

- Fuel Conversion Efficiency

- up to 85%

- Control System

- PLC/SCADA based

- Emission Standard

- Complies with local pollution standards

- Capacity

- Ranging from 500 kW to 10 MW

- Output Type

- Electricity and Heat

- Operating Temperature

- 800°C to 1100°C

- Automation Grade

- Semi-automatic/Automatic

- Feedstock Type

- Agricultural, municipal, and food waste

- Lifespan

- 15-20 years

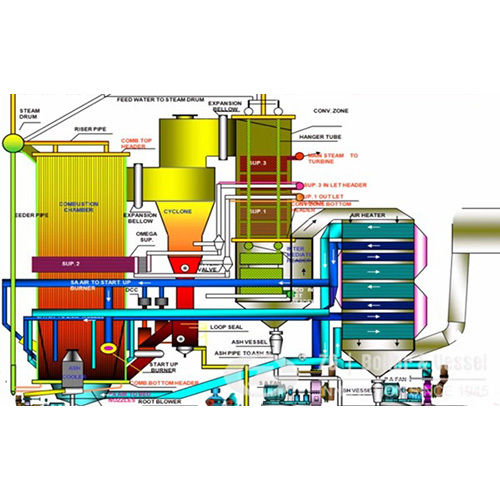

About Biodegradable Waste to Energy Power Plant

Versatile Applications Across Surfaces and Media

The Biodegradable Waste to Energy Power Plant brings dynamic energy conversion to diverse application media, including agricultural fields, municipal facilities, and food processing surfaces. Designed for industrial sites, municipalities, and rural setups, its adaptable system efficiently processes feedstock rich in biodegradable content. Usage types range from partial to continuous operation and support both new installations and existing infrastructures, ensuring flexibility for every project requirement.

Domestic Leadership and Global Reach: Supply and Dispatch

Recognized as a leader in the Indian energy market, this power plant is poised for rapid deployment with Stock Ready status. Covering pan-India and global export markets, every unit is packed securely for instant FOB dispatch from major Indian ports. International clients can benefit from tailored List Pricing and efficient packing and dispatch solutions, positioning this system as an ideal, cost-effective solution for sustainable waste management worldwide.

FAQs of Biodegradable Waste to Energy Power Plant:

Q: How does the Biodegradable Waste to Energy Power Plant generate electricity?

A: The plant utilizes a cutting-edge conversion process, transforming agricultural, municipal, and food waste feedstock into clean electricity and thermal energy through high-temperature combustion and a PLC/SCADA-controlled system.Q: What are the main benefits of installing this power plant?

A: By investing in this power plant, users achieve waste reduction, energy self-reliance, reduced emissions, and compliance with local pollution standardswhile generating electricity and heat from renewable resources.Q: Where can the plant be installed for optimum results?

A: It suits diverse locations including municipal waste facilities, agricultural processing plants, and industrial sites. Installation is tailored by size and cooling system to suit local requirements and available surface area.Q: What is the process for procuring and installing the power plant?

A: Clients can Add to Cart and initiate procurement; turnkey or EPC (Engineering, Procurement, Construction) installation is then executed, ensuring a hassle-free, professionally managed setup.Q: When will my order be packed and dispatched after purchase?

A: With Stock Ready status and robust packing facilities, your order is securely prepared and dispatched promptly from major Indian ports following completion of all formalities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Waste to Energy Power Plants Category

Waste Management Waste to Energy Power Plants

Gross Calorific Value : 41004300 Kcal/kg

Shape : Other, Customized Modular Construction

Dimension (L*W*H) : As per client specification

Fixed Carbon : 2830%

Volatile Matter (%) : 3436%

Material : Multiple Waste Streams (Household, Industrial, Agricultural)

Electricity Generation Waste to Energy Power Plant

Gross Calorific Value : 35005000 Kcal/kg

Shape : Other, Modular Plant Structure

Dimension (L*W*H) : Customized (e.g., 50m x 30m x 20m for 20MW plant)

Fixed Carbon : 1020%

Volatile Matter (%) : 6070%

Material : Mild Steel, Stainless Steel, HeatResistant Alloys

Waste to Energy Plant

Gross Calorific Value : >4000 kcal/kg

Shape : Other, Rectangular / Modular

Dimension (L*W*H) : Depends on design, typically 15m x 10m x 8m

Fixed Carbon : 20 30%

Volatile Matter (%) : 40 45%

Material : Mild Steel Structure, Highgrade Boiler Components

Solid Waste to Energy Power Plant

Gross Calorific Value : 35004500 kcal/kg

Shape : Other, Rectangular Modular

Dimension (L*W*H) : As per Design Typical: 40m x 20m x 18m

Fixed Carbon : Around 1525%

Volatile Matter (%) : 4050%

Material : Mild Steel Structure with Advanced Alloy Components

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS