WTE Plant

WTE Plant Specification

- Dimension (L*W*H)

- 18 x 11 x 9 m

- Gross Calorific Value

- 4500-5500 Kcal/kg

- Size

- 6-25 mm

- Coal Calorific

- Comparable to Sub-bituminous Coal

- Product Type

- Waste to Energy (WTE) Plant Fuel

- Material

- Mixed Municipal Solid Waste

- Shape

- Granular/Pellet

- Moisture (%)

- 18-25%

- Sulphur Content (%)

- 0.6-1%

- Fixed Carbon

- 15-22%

- Phosphorus Content (%)

- 0.02-0.07%

- Volatile Matter (%)

- 22-28%

- Ash Content (%)

- 15-22%

- Weight

- Up to 30 Tons/Day Processing

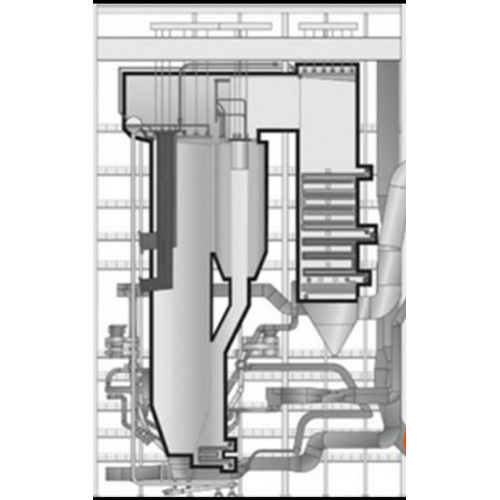

About WTE Plant

Having great knowledge and experience in this area, we are actively committed towards proposing the best in quality WTE Plant. This type of system is engineered to be utilized for incinerating garbage as well as creating steam. The presented proposed plant helps maintain operation internally due to its high efficiency, constant performance, smooth functioning and low maintenance need. Made of top of the line parts & components with approved engineering & developing techniques, the WTE Plant varies in sizes, designs, capacities and specifications.

Efficient Waste Management and Energy Recovery

This WTE plant streamlines the conversion of mixed solid and industrial wastes into valuable energy. With fully automated PLC-based controls and robust materials, it operates efficiently at high temperatures, ensuring optimal waste processing and reliable power output while mitigating environmental impact.

Advanced Compliance and Safety Features

Meeting stringent CPCB and Euro emission standards, the plant incorporates state-of-the-art filtration and combustion technologies. Its design significantly reduces harmful emissions, supporting regulatory compliance and safer, cleaner community environments.

Versatile Feedstock Handling

The system can process a wide range of input materials, including municipal solid waste, industrial byproducts, biomass, and RDF, all within size and moisture specifications. This flexibility enhances plant utility across various sectors, ensuring continuous and stable energy generation.

FAQs of WTE Plant:

Q: How does the WTE plant convert waste into energy?

A: The plant uses thermochemical conversion at temperatures ranging from 8501100C to process mixed solid waste and RDF. Heat generated from the combustion is used to produce steam, which drives turbines to generate electricity efficiently.Q: What types of input materials can be processed in the plant?

A: The system is engineered to handle municipal solid waste, industrial waste, biomass, and Refuse Derived Fuel (RDF) with granular or pellet shapes. The recommended size is between 625 mm and moisture content between 1825%.Q: When is it suitable to use this WTE plant?

A: This plant is suitable for municipalities or industries seeking sustainable waste management and reliable energy production, especially when consistent mixed waste streams are available, and theres a need to meet regulatory emission standards.Q: Where can this WTE plant be installed?

A: Designed for flexible deployment, the plant can be installed at municipal waste collection sites, industrial areas, or near biomass sources across India, wherever centralized power generation and waste disposal solutions are required.Q: What is the benefit of using a fully automatic control system in this WTE plant?

A: The PLC-based control system ensures efficient, consistent operations, minimizing manual intervention. This automation enhances safety, optimizes process parameters, and ensures compliance with emissions and energy output standards.Q: How does the plant ensure compliance with emission standards?

A: It includes advanced emission control and filtration measures, guaranteeing all outputs meet or surpass the requirements set by CPCB and Euro norms, thus mitigating the release of harmful substances into the environment.Q: What energy output can customers expect, and how does it compare to conventional fuel sources?

A: The plant can deliver up to 10 MW of electrical power, with an energy conversion efficiency of 2834%. Its output is comparable to sub-bituminous coal in calorific value, making it a viable alternative to traditional fossil fuels.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS